0

Points of sales

0

Nations

0

Products

70

FACTORIES: 2

USED AREA: 44,200 m2

THE AUTOMATION RATE REACHED

81.38%

EMISSIONS TO ENVIRONMENT

ARE DEDUCTED BY

1,326 ton CO2/year

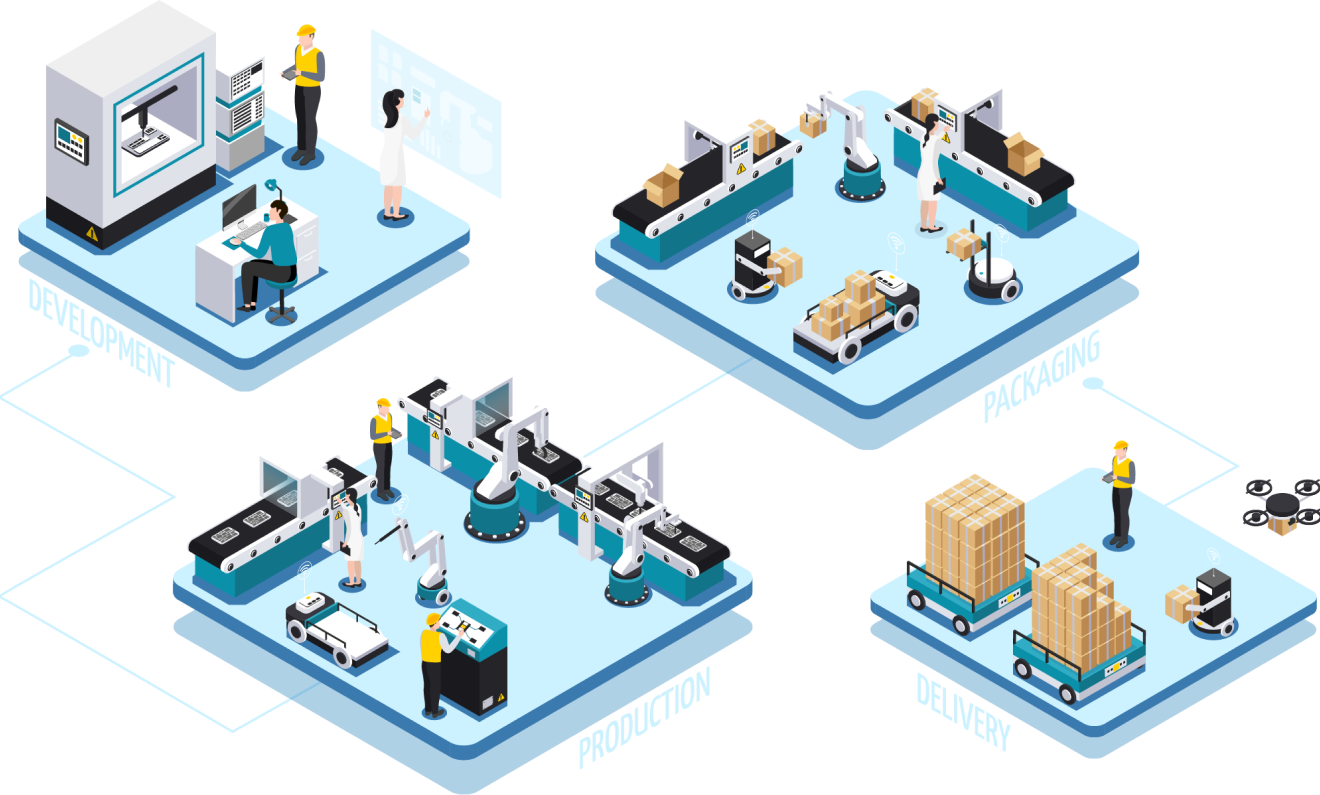

Considering technological applications and digitization as the key factors that help maintain FlexOffice’s business development and competitiveness, FlexOffice has focused its investments on them over the past several years. In particular, this investment process has been accelerated post Covid-19 and gained many very positive results.

FlexOffice has applied many high-productivity automatic technology lines. The automation rate at the South Thien Long factory has been raised to 81.38% from 78.86% at the end of 2021. As a result, FlexOffice overall productivity has been increasingly improved. FlexOffice wants the trust and satisfaction of customers not only to come from product quality but also from purchasing experience, which is quite challenging, as FlexOffice provides customers with more than 1 billion products of various kinds every year. Therefore, in addition to the dedication of employees,FlexOffice has actively improved and innovated sales and delivery methods. FlexOffice has been applying the DMS to manage the distribution of goods to the market. This system helps employees to capture instant information about the number of online deals, sales, revenue, liabilities, inventory, etc. to timely support the group in making business decisions appropriate to market situations.

In addition, FlexOffice has also applied the Warehouse Management System (WMS) in central warehouse management in Le Minh Xuan Industrial Park. The system helps efficiently control and manage warehouse operations, thereby ensuring the prompt and effective delivery of goods to customers and optimizing FlexOffice’s omnichannel operating costs. FlexOffice’s modern technology system combined with its team that always puts customers at the center of its business has helped FlexOffice increasingly bring better experiences to its agents as well as customers.

All operations of FlexOffice are now operating on the SAP-HANA technology integrated with satellite transaction application systems, in which all applications are connected to ensure smooth and instant data. Technology and people are two inseparable factors in digital transformation.

FlexOffice focused on researching, self-designing, and manufacturing machinery and equipment for use in production. FlexOffice also promoted designing and manufacturing molds to replace imported ones in order to reduce product costs and improve production capacity and competitiveness.

Mold making was oriented to apply high technology for mold structures, optimized molds according to press capacity, and automatized injection molding in order to make semi-product production more efficient and with higher performance.

In addition, the research and manufacture of molds for the production of other types of semi-products, such as injecting multiple plastic components on the same semi-products, was also ongoing, in order to reduce the number of product components and diversify product models.

FlexOffice imported modern machinery and technologies from advanced countries, such as injection machines from Japan to optimize the SP manufacturing processes and enhance the quality of SPs. The arrangement and reorganization of factories and production stages towards modernization and automation are conducted across the group production to further boost production efficiency.

In 2022, FlexOffice improved the structures and parameters of various molds to make the best use of the current machinery capacity.

AUTOMATION RATE

81.38%

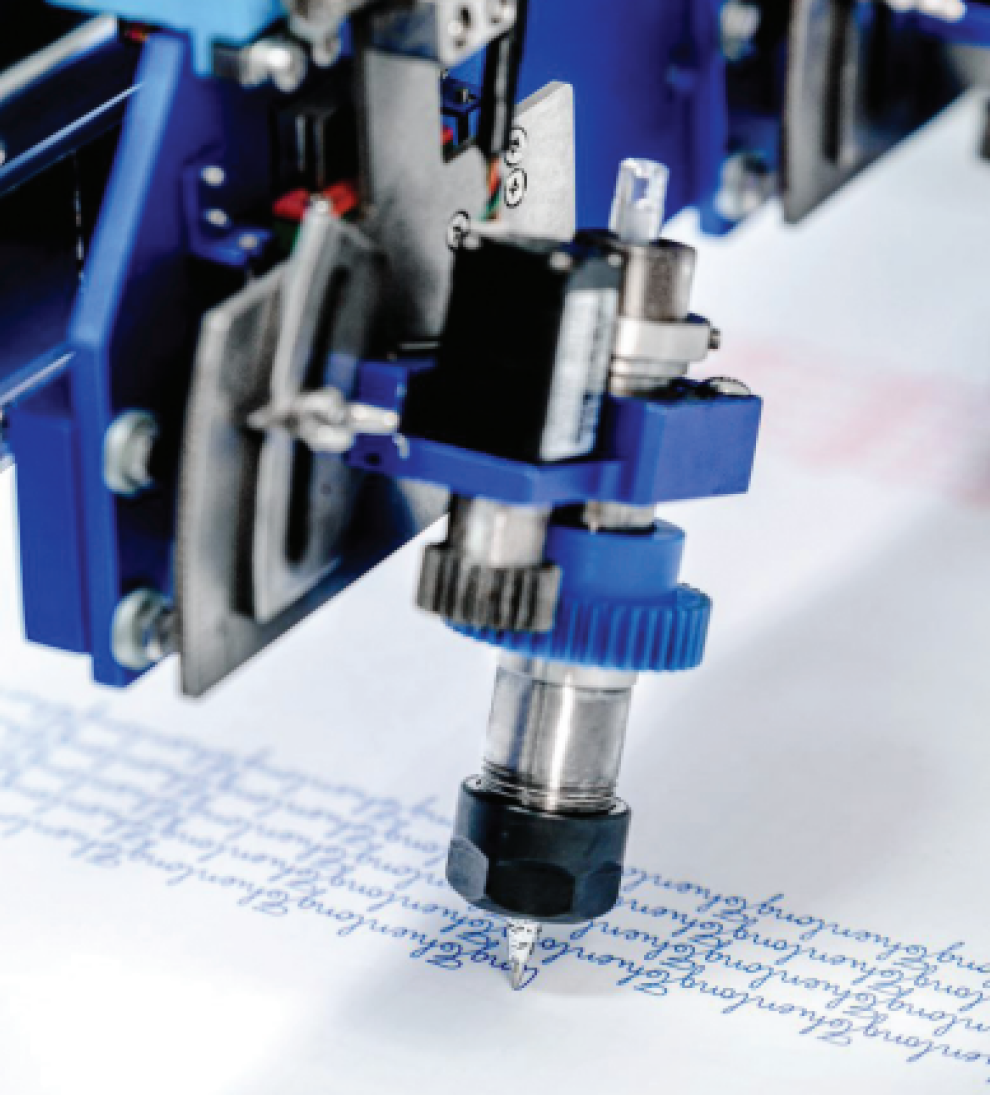

During the year, FlexOffice made many renovations to adapt to the market situation and increase the automation rates in its factories. The year saw many high-productivity automatic technology lines put into operation, along with hot runner molds and plastic multi-component molds. FlexOffice mastered precision mechanical technologies to continue manufacturing pen tips with Swiss and German machinery and equipment. It has invested in and applied energysaving injection machines with high accuracy. The automation rate at South Thien Long was raised to 81.38% compared to 78.86% at the end of 2021. As a result, FlexOffice’s overall productivity has been increasingly improved.

Since its establishment, FlexOffice has considered the GREEN factor as one of the top criteria in its operation. Accordingly,FlexOffice has developed a standard wastewater treatment system that does not cause environmental pollution while saving energy and raw materials.

EMISSIONS TO ENVIRONMENT ARE DEDUCTED BY

1,326 ton CO2/year

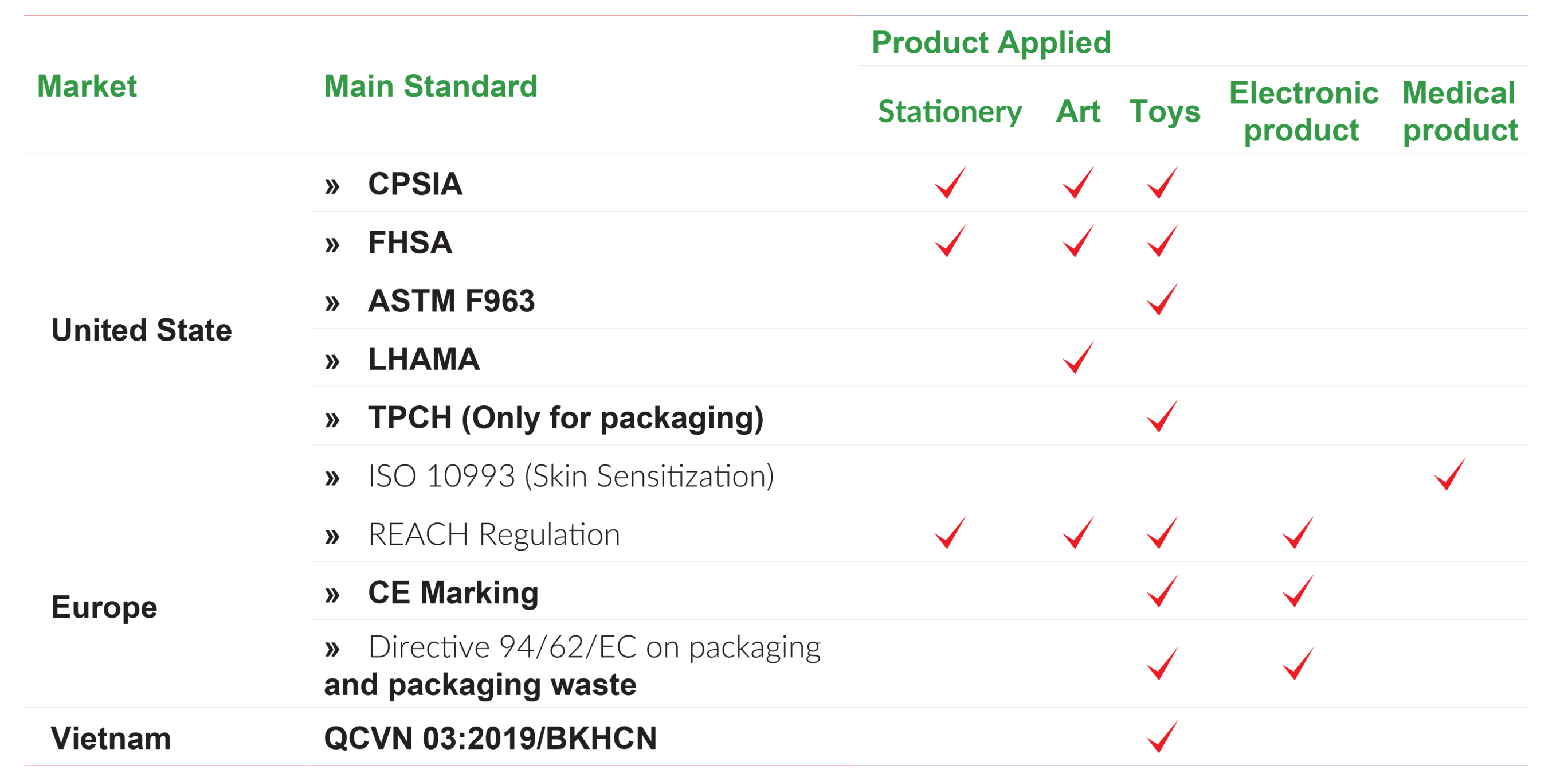

FlexOffice applies a strict control process at all stages, from supplier selection, input material inspection, examination of quality in each production stage and control of finished product quality in order to ensure the quality and safety of all products before they are put on the market.

To inspect and test products, FlexOffice uses a laboratory according to ISO/IEC 17025:2017, equipped with specialized equipment such as a German Hutt pen tester, absorption spectrometer, electrical conductivity meter, aging meter, viscosity, pH, humidity, etc. Therefore, all test results are highly accurate and reliable.

FlexOffice’s products fully meet the safety standards and certifications by the U.S. and EU, as well as those by Vietnam, ensuring safety for consumers, especially children, according to the product grouping table as follows: